Solutions for the space domain

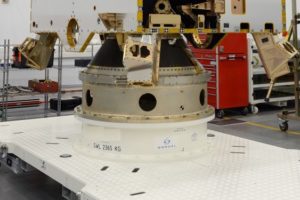

Since 2008 GRADEL is developing special purpose machines and tailored made solutions for the space domain. Due to our experience in electro-mechanical engineering, automation and dynamic axis control, GRADEL has developed extensive know-how for the realization of complex equipment, compliant to the specifications of our customers. Our main product group in space is Mechanical Ground Support Equipment (MGSE), where we have a complete range of equipment for handling S/C or parts of it.

The following MGSE’s are typical products of GRADEL: Multipurpose Trolleys, Hoisting Devices, Horizontal and Vertical Lifting Devices, Integration Stands and adapter rings for the assembly integration and test of all types and sizes of Satellites, as well as Equipment of CATR facilities to test the antennas of the satellites.

GRADEL is providing MGSE elements for the instrumentation of satellites as well. These elements are dominated by special requirements concerning magnetic compatibility, cleanliness and precision.

In addition GRADEL is developing flight hardware like brackets, interface rings, cable feed through and small deployable elements for satellites.

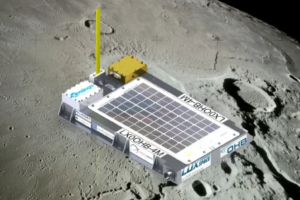

GRADEL has provided equipment among others for the following space programs: Alphabus, EDRS, Electra, Esail, Euclid, Eurostar Neo, ExoMars, Juice, Moonmission M4, MTG, Proba3, SGEO and Solar Orbiter.

GRADEL is supported in some of its space activities by Luxembourg and by the European Space Agency (ESA).

GRADEL Ultralightweight Department has developed a manufacturing technique which reduces and optimizes the weight of the parts for flight hardware. The process has the ability to orient stiffness according to the desired functions and load cases. It has the latest computational power to help you with your design challenge in house. Thus, creating intelligent ultralight structural components that can reduce weight down to 70% compared to their counterparts. The advantages of the process are almost limitless due to the flexibility in choice of material and excellent repeatability with robotic winding equipment.

CONTACT US

Pierre-Emmanuel Meiers

T : +352 39 00 44 74